Effective supply chain management (SCM) is all about making the right decisions. Whether this involves which suppliers to use, how much inventory to purchase, or how to distribute your inventory, good decision-making is crucial to ensure a seamless flow of operations. This is also where supply chain leaders face the biggest challenge, as one wrong decision could snowball into bigger problems like delays, bottlenecks, disruptions, quality issues, and higher costs.

In this article, we’ll walk you through a guide to making smarter supply chain decisions to streamline your operations, explore the factors that influence those decisions, and share how to optimize the decision-making process in ecommerce.

Why we’re talking about supply chain decisions

Every decision made throughout the supply chain influences the flow of goods and processes. Strategic supply chain decision-making ensures a smooth workflow and efficient inventory movement, which improves operational efficiency and reduces costs. All of this adds up to increase your bottom line.

The right decisions help you ensure that your supply chain workflow remains uninterrupted. They ensure that you work with the right suppliers to maintain quality and cost efficiency. Moreover, your decisions impact things like stock availability as you decide when to replenish inventory and how much to order.

It even influences fulfillment efficiency, as your decisions influence which delivery partners you work with and how shipping is prioritized. You decide where orders are shipped from and which shipment method to use, which then influences things like delivery speed and shipping costs. You could significantly reduce transit time and costs with strategic supply chain decisions.

As such, it’s crucial to prioritize the supply chain decision-making process to streamline every aspect of your operations.

Understanding the levels of supply chain decisions

Supply chain decision-making involves three main levels:

Strategic

Strategic decision-making happens at the top level of the supply chain. This is mostly concerned with long-term planning, helping to lay the foundation for your entire supply chain operation. For example, strategic decisions include deciding on product offerings or choosing suppliers.

Tactical

Tactical decisions are mid-level, involving medium-term actions. The focus here is on implementing the strategies laid out at the higher level. For example, tactical decision-making involves determining your warehouse capacity and deciding on whether to outsource to a 3PL or manage fulfillment yourself.

Operational

Operational decision-making is concerned with day-to-day activities and short-term actions that help to keep the supply chain moving. For example, operational decisions involve deciding on which carrier to use for a particular order and daily inventory forecasting.

Key factors that influence supply chain decisions

There are several key areas of the supply chain that should be considered in the decision-making process.

Supplier selection

The supplier selection process is one of the most vital aspects of supply chain decision-making. This is when businesses decide on which suppliers and manufacturer to use for sourcing their inventory or raw materials. Decisions are usually influenced by factors such as cost, quality, ethicality, reputation, location, and reliability.

Decision makers will need to strategically balance cost and quality when choosing suppliers. Most importantly, you need to source goods from suppliers who are aligned with your company’s goals.

Production and manufacturing

In supply chains where products are built or created, decision-makers also have to plan out various aspects of the manufacturing operation. This involves things like facility locations, production processes, and production timelines. These decisions are focused on improving production efficiency while minimizing cost and maintaining quality control.

Inventory management

Inventory management is one of the most important decision areas in supply chain management. The right decisions help you strike the right balance between supply and demand, ensuring that businesses can maintain optimal stock levels without the risk of overstocking. Timely replenishments, accurate demand forecasting, and efficient procurement planning are crucial for effective inventory management.

Logistics and fulfillment

Logistics play a vital role in your supply chain operations, which makes them another major decision area. Businesses need to consider cost and lead times to improve transportation efficiency while reducing expenses, and therefore must make strategic decisions about which transportation provider and transportation modes to use.

It’s also crucial to plan out your logistics network and optimize delivery routes to improve speed and cost-efficiency. This helps to keep your supply chain operations running smoothly while improving customer satisfaction with timely deliveries.

Common challenges when making supply chain decisions

Although ecommerce businesses take care to consider all the key factors when making supply chain decisions, there are several challenges that could disrupt the process. Some of the biggest challenges affecting supply chain planning and decision-making include:

- Long transit times: Long transit times are a leading cause of supply chain bottlenecks, making it difficult to quickly respond to demand and market changes. Decision makers may not always be able to make accurate decisions that account for unexpectedly long transit times and delays, which could disrupt supply chain operations.

- High fulfillment costs: When fulfillment costs are high and often unpredictable, it can be hard to make decisions for the future. Decision-makers must often consider cutbacks in other areas to make up for these high fulfillment costs, which could subsequently impact quality, efficiency, and the customer experience if handled incorrectly.

- Limited data visibility: Without visibility into what’s going on in various areas of the supply chain network, you lack the information needed to make accurate decisions. When you make uninformed decisions based on assumptions and outdated data, it can create various problems in your supply chain decisions.

How to optimize supply chain decisions for your ecommerce business

Better supply chain decision-making is all about leveraging data and supply chain best practices. Here are a few tips to optimize supply chain decisions for your ecommerce business.

Leverage data-driven insights

Start by making the most of the data you have access to to inform different aspects of your supply chain decision-making.

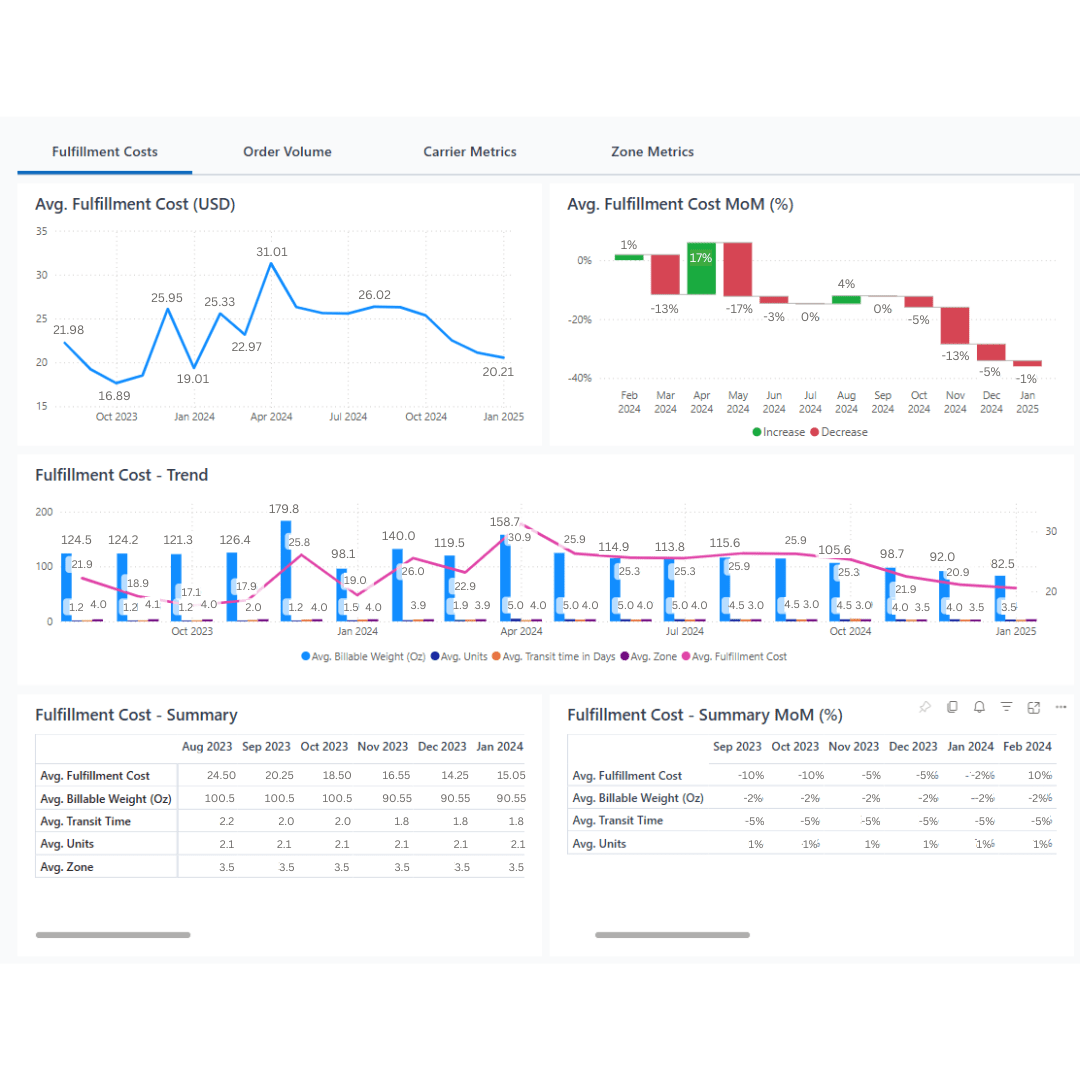

Leverage supply chain analytics to collect real-time data about your performance across various supply chain processes. This data can give you insights into how different activities and functions are performing, allowing you to make optimizations that will improve overall efficiency.

For example, if you find that you’re not fulfilling enough orders per day, you could look into your fulfillment process and make strategic decisions to target inefficiencies. This may involve a decision to leverage automation tools to speed up picking and packing, for instance.

You should also leverage data in decisions regarding:

- Inventory distribution: Look into your inventory performance across various warehouses and decide on the optimal inventory placement strategy. That way, you can maintain optimal inventory levels while reducing shipping costs and transit times.

- Demand forecasting: Gather insights about historical inventory performance, current market trends, and consumer buying behaviors to identify patterns and make accurate predictions about your future inventory needs. This ensures that you stock up on time so you can stay prepared to maintain sufficient stock and effectively meet demand surges. Alternatively, you can avoid stocking up on more inventory than you actually need, helping you minimize dead stock.

The power of a distributed inventory model

Ecommerce decision-makers can streamline some aspects of their supply chain strategy by leveraging inventory models that have been proven to be successful. This almost always involves implementing a distributed inventory model where you place inventory in multiple fulfillment centers, instead of relying on a single warehouse.

As such, you can store inventory closer to your customers and ship out orders based on proximity and inventory availability. When you ship out orders from the nearest fulfillment center, you can significantly reduce shipping costs while improving delivery speeds. Not only does this improve the customer experience, but it will add to your bottom line as a whole.

With this approach, your biggest decision is where to place inventory to best meet customer demand. Fortunately, machine learning algorithms like the ones powering the ShipBob Inventory Placement Program can take the guesswork out of this process. This automatically suggests the optimal distribution strategy based on your inventory performance and regional sales data.

Partner with an expert supply chain platform

en it comes to making smart supply chain decisions, it’s always helpful to have input and support from an expert partner. Technology-driven supply chain platforms like ShipBob offer you that expert opinion, as well as enhanced visibility and best practices to effectively streamline the decision-making process.

Your supply chain partner should feel like an extension of your business, not just another vendor. This approach to your partnership ensures that they have your business’s best interest at heart, and will advocate for your business at every turn.

Simultaneously, they should be experts in and offer certain tablestakes capabilities, such as:

- Omnichannel fulfillment (DTC and B2B)

- Comprehensive data analytics on your supply chain functions

- Demand forecasting tools

- Real-time inventory tracking

- Smart inventory distribution recommendations

- An extensive global network of warehouses for you to leverage

- Customization options for orders (i.e., braded custom packaging)

- 2-day shipping options

If your partner has mastered these core functions and services, you can more safely trust any guidance they offer on key elements in your warehouse, fulfillment, and supply chain operations.

“Our area of expertise is not logistics or inventory management, so we lean on ShipBob a lot for that. We’ve learned so much about this industry since working with ShipBob, as they are true supply chain experts, which has been good for everyone on our team.”

Callie Tivnan, E-commerce Manager, and Christina Williams, Customer Success Manager at Barefaced

How ShipBob supports smarter supply chain decisions

With sophisticated supply chain technology and world-leading fulfillment solutions, ShipBob empowers you to make smarter decisions across your supply chain network.

Tap into a global fulfillment network for seamless expansion

ShipBob’s expansive global fulfillment network consists of dozens of locations across multiple continents. This facilitates easy – and strategic – geographic expansion, so you can effectively scale your global supply chain.

Your brand can take advantage of this global fulfillment network to store inventory closer to your international customers. This ensures faster delivery times, helping you enhance satisfaction and effectively meet customer expectations across borders. Storing and fulfilling inventory from within the country you’re shipping to also cuts down on cross-border complexities, saving you time and simplifying much of the decision-making involved in your international commerce.

“Shipping cross-border is never easy, especially when you’re shipping a product that qualifies as a dangerous good since our products contain alcohol. By storing inventory in ShipBob’s facilities within the countries or near the geographies we’re shipping to, we can bypass a lot of the complexities of international shipping. It makes our lives significantly easier. But more importantly, shipping locally instead of internationally is better for customers. You can always navigate cross-border complexities, but you can’t undo a customer’s stressful delivery experience.”

Sergio Tache, Founder and CEO of Dossier

Distribute intelligently with ShipBob’s Inventory Placement Program

Instead of making last-minute stocking decisions, ShipBob helps you plan ahead and strategically storing your inventory at key locations using ShipBob’s Inventory Placement Program to help you reduce shipping costs and transit times.

The program uses a proprietary algorithm to determine the optimal inventory allocation strategy based on your historical sales data and inventory performance. That way, you can easily decide where to store your inventory and how much inventory you need at each location. This helps you significantly reduce shipping costs while speeding up deliveries.

“Before IPP, we had a team of 3 people who were focused on distributing products correctly within the ShipBob network. In order to do that, we had to have a good understanding of the sales velocity in each region. They had to pay close attention to how stocked each warehouse was. Because if you don’t distribute products correctly, orders are going to ship from a farther warehouse which is going to cause longer transit times and cost more money. It was time-consuming for us to distribute and rebalance inventory on our own.

With IPP, we can send products to one location and then ShipBob’s algorithms and technology use our historical order data to replenish inventory to each facility. That removes the responsibility from us. We can send inventory to one facility and then forget about it. When we first got started, we checked how ShipBob’s IPP was distributing our inventory based on the models we created when we did distribution in-house – they were on point. ShipBob’s machine learning data works. They took a container with 1,000 SKUs and knew exactly which inventory needed to go to which facilities.”

Cesar Contreras, Head of Supply Chain of Wholesome Goods

Fulfill quickly with our 2-Day Express Shipping

ShipBob empowers you to effectively meet customer expectations with fast and reliable shipping. Solutions like our 2-Day Express Shipping program ensure that customers in the contiguous US receive their orders within two business days, even if you’re shipping from just a single fulfillment center, so you don’t have to scramble to make decisions about which carriers can or cannot provide it.

Access advanced analytics for better decision-making

ShipBob’s advanced analytics dashboard provides you with essential metrics to track supply chain performance and optimize your operations accordingly. You can get real-time and historical data insights that can inform your order routing and inventory allocation strategies. This allows you to significantly reduce inventory and fulfillment costs to improve your bottom line.

Similarly, the dashboard provides you with key insights into shipping performance. This helps you make informed decisions on how to optimize shipping methods for cost reduction and improved efficiency.

Leverage automations to make decisions for you

The more supply chain decisions you can automate, the more time and money you’ll save. ShipBob uses automation at key points throughout our technology and warehousing operations to take as many small or menial decisions off your plate as possible. For example, ShipBob automates:

- Box selection for each order through Cubiscan technology that calculates the optimal packaging and container size for each unique combination of products

- Packing specifications through our WMS, which includes built-in visuals and prescriptive flows that tell associates exactly what to do

- Carrier rate comparison using our multi-carrier selection software to help automate shipping

- Inventory replenishment notifications to remind you to reorder when stock dips below a certain threshold

- Certain condition-based activities (such as whether to add a gift note to an order), which merchants can configure through ShipBob’s Automation Rules in their dashboard

“When we go onsite to one of ShipBob’s fulfillment centers, the packers know our products so well, because ShipBob’s step-by-step packing flow shows them just what to do. That way, they know exactly which dividers go with which candles, which size box each combination of products goes in, and how to package it correctly. It even includes GIFs that show packers precisely how to do it! It’s a spectacular level of service that only comes from combining automative technology with people that really understand our business.”

Rachel Tannenholz, President, and Melissa Mosheim, Director of Logistics at Aroma360

For more information on how ShipBob can help you streamline your supply chain decision-making, click the button below to get in touch.

Supply chain decision FAQs

Below are answers to the most commonly asked questions about supply chain decisions.

What are the main types of supply chain decisions?

The main types of supply chain decisions are:

- Strategic, which involves long-term decisions at the top level

- Tactical, which involves resource planning at the mid-level

- Operational, which involves decisions about everyday operations

What tools does ShipBob offer to support supply chain decisions?

ShipBob provides powerful supply chain technology that integrates with various processes within the supply chain network. This enables you to get real-time visibility into your performance so you can make informed decisions on how to optimize it.

Why would companies want to speak with supply chain decision-makers?

Companies need to involve supply chain decision-makers because sometimes, business matters that appear unrelated to the supply chain may actually deeply impact it. Looping in key supply chain decisions makers helps ensure that the supply chain in question is protected, operations are not disrupted, and costs are kept in check.

How do environmental factors influence supply chain decision-making?

With the increasing global movement toward sustainability, many ecommerce businesses are focused on building a more sustainable supply chain. When this is the case, the supply chain decision-making process carefully considers environmental factors at play in every function and stage to minimize environmental impact.